Common Plumbing Code

Violation

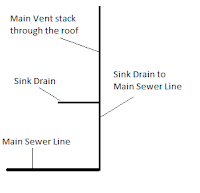

Drain Venting

Air Admittance Valves (AAV) and Mechanical Vents

Why do we need Venting on drain lines

and What is it?

Without venting, our drains would hardly work,

and they would make gulping noises due to negative air pressure in the

lines. When water moves down our drains

the empty space that was filled with air now needs to be replenished with more

air. Our drain system can be related to

a full bottle of water being emptied. If

we take the cap off of the bottle and turn it upside down to empty the bottle,

we will notice 2 reactions occurring.

1. The bottle creates a vacuum which

sucks air into the bottle to help drain the water more quickly. We will feel the bottle jump and make a

gulping noise while the water is draining.

2. We will notice the bottle being

pulled together at the top where the air is replacing the water.

v The reason the bottle starts to gulp

air inside is because we are creating negative pressure. By tipping the bottle completely upside down

we close off its only entrance for air or water to pass through. The bottle is trying to replace the area that

was once occupied with water for an exchange of air. The reason the bottle actually jumps and

gulps has to do with the amount of water that is trying to be released. We can

refer to the water pressure caused by the gravity as head pressure. The amount of head pressure blocking the

outlet of the bottle will determine how much velocity and force it takes to

make the bottle jump.

v The bottle is being squeezed together

at the top while draining because of negative air pressure in the bottle. Negative air pressure is created when a

closed room or container is being deprived of the air inside of it. Referring back to our plastic bottle example,

the plastic is ductile so it makes the bottle suck together where it is lacking

air.

Click here to check out what happens when you

improperly vent a tanker car, this is an extremely interesting example of what

kind of force negative pressure can have.

These are major concerns

with the venting of your drain pipes.

Another concern is the added pressure when drains tend to back up. Vents also allow for another place for drain

pressure to escape. Sometimes when a

home’s drain line backs up, it will push the water or sewage through the main

vent stack. This may cause the water to come

out of the stack opening on the roof.

This would be referred to as positive air pressure.

Venting allows for the

air in the line that is being filled with water to be replaced immediately with

more air. This will sustain a neutral

air pressure which will allow your drains to work properly. Properly working drains always keeps a

sufficient amount of water in the traps.

Drain traps are extremely important without them sewer gas would be

present in our home. The sewer gas is

terrible for anyone’s health and should not be breathed in. Without proper venting the water that is

supposed to be in the trap may be siphoned into the line in order to change the

negative air pressure back to neutral.

An absence in water leaves the line wide open to your homes main sewer

line, this is where the sewer gas will enter your home.

Air Admittance Valves (AAV) or Mechanical Vents

AAV’s or Mechanical vents

work on a spring loaded valve that will let air in. When positive pressure comes up through the

line it closes up tightly, not letting any water or air escape. These devices are basically check valves that

only allows air to be sucked into the system.

Most of the time we see

these devices underneath the sink in the vanity or buried in the wall. The technology has developed significantly

over the years. With new technology and

extensive testing, a more reliable product has been developed.

Mechanical Vent was the

original term for these devices. I feel

the term has been changed to AAV so that people will use them. Changing the name has confused many when

trying to decipher the plumbing codes. A

Mechanical vent is the same as an Air Admittance Valve in all code books.

Why someone might use a AAV?

Sometimes you may run

into a situation were the main vent stack or any branch vents are no were close

to where you want to put a sink, toilet, or shower. This makes it possible to vent your drains in

the hardest spots. You also may have

existing piping or HVAC Ducts in the ways of here you need to run your vent

pipe. AAV’s gives you a cost effective

solution to adding or moving your drains.

Some plumbers and home

owners find this to be an amazing product to complete their task. But the best plumbers will complete your job the right way the first time, so you will never

have any unexpected issues later down the line.

Are AAV Compliant to Code?

The simple answer to this

is “No”. In the state of Illinois, the code strictly

permits against the use of a mechanical vent or AAV. As far as code goes for Residential and

Commercial work you will want to check with your Local Municipal Inspectors. In

some cases, the village may allow the use of this device. You must know that every city is slightly

different with their codes but in most cases throughout the United States they

are not allowed and should not be allowed.

Let’s take a look at what venting systems are used by the best Plumbing Companies.

Difference between a dry and wet vent

A Dry vent

is a simple one drain system where the vent will not serve as another’s drain.

A wet vent

will tie into another fixtures drain, thus the term wet drain. A wet vent may share a common vent stack but

will tie in at different heights.

v A simple example of a wet vent would

be a bathroom were the main vent stack is offset to one side of the room. The toilets drain will run directly to the

main stack were it goes out to the sewer and is vent from the stack that goes

to the room. Now the sink will run a

vent branch up to the stack and the drain will tie into the toilets drain pipe

before the toilet vents in the stack.

Types Plumbing Venting

Common Vent/Drain System

Branch Venting

Is extremely common in homes it is

were drains share a branch vent pipe which ties into the main stack.

Loop Venting The vent goes up and loops back down and ties back

into the drain line for the fixture.

Commonly only used for sinks.

This system is normally allowed for single sink systems like in a

kitchen island where it is impossible to tie into a vertical stack. Some Municipalities allow one loop vent per

house. Before the loop vent ties back

into the drain it can either branch off to be properly vented or not.

Circuit Venting